Amaze your customers with particle foam

> Premium product quality

> Low costs, less CO2

> Flexible and immediately ready for use

Get to know all of our services.

> Premium product quality

> Low costs, less CO2

> Flexible and immediately ready for use

The BEAD.MACHINE shows its full potential in combination with additively manufactured moulds: Due to its low weight, short heating and cooling times are possible – and therefore fast cycle times. The changeover or adaptation of the moulds are just as quick.

Since the moulds are manufactured at short notice using 3D metal printing, you can react flexibly to new market situations – always staying one step ahead of your competitors.

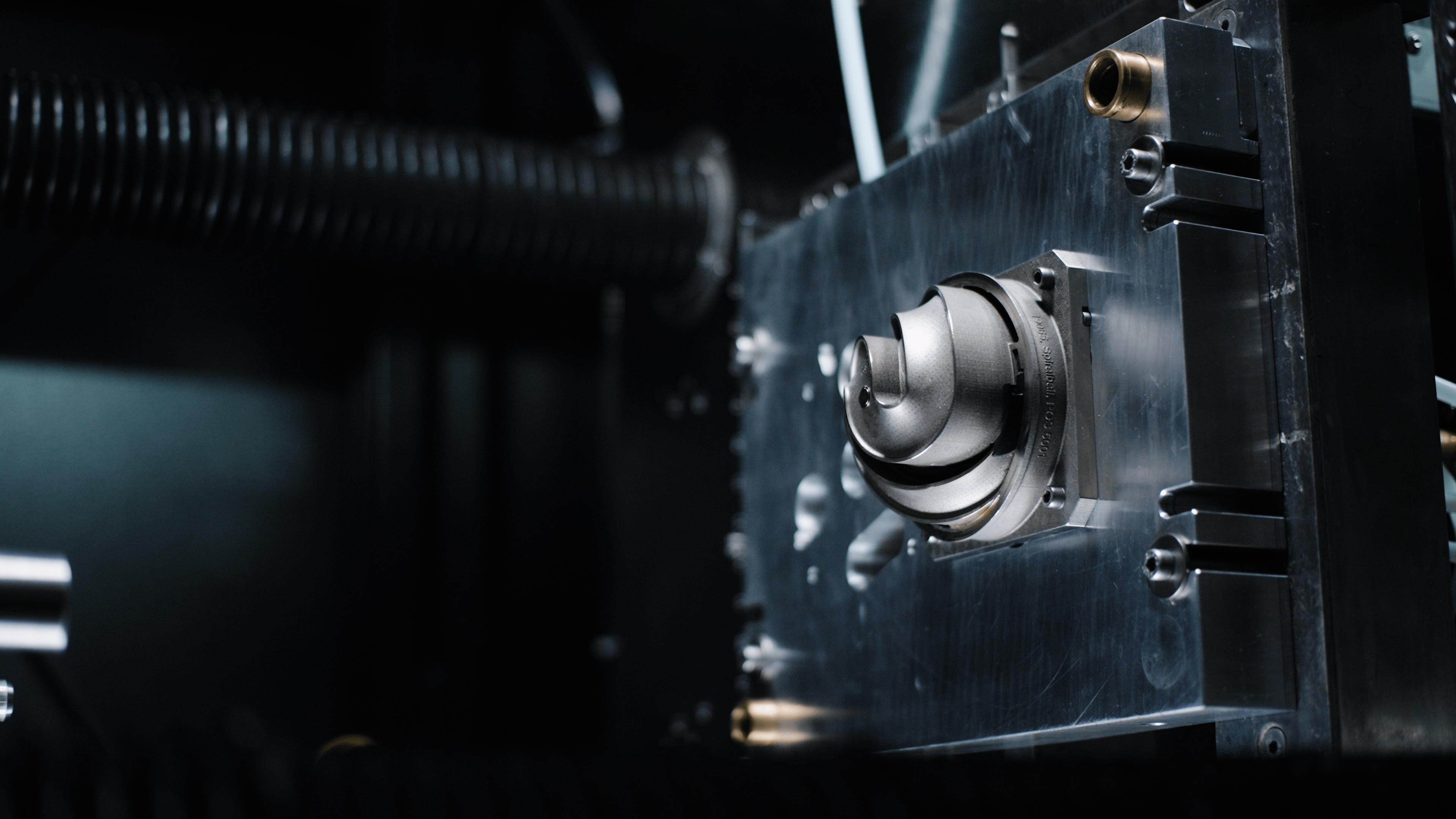

Plastic inlays can be easily enclosed with particle foam and firmly bonded into a product with the BEAD.MACHINE. Our spiral ball demonstrator – developed together with the WSVK – shows how dimensionally stable and at the same time flexible the result can be.

The innovation allows you to find new solutions and open up new application areas such as in the lifestyle or technical sectors.

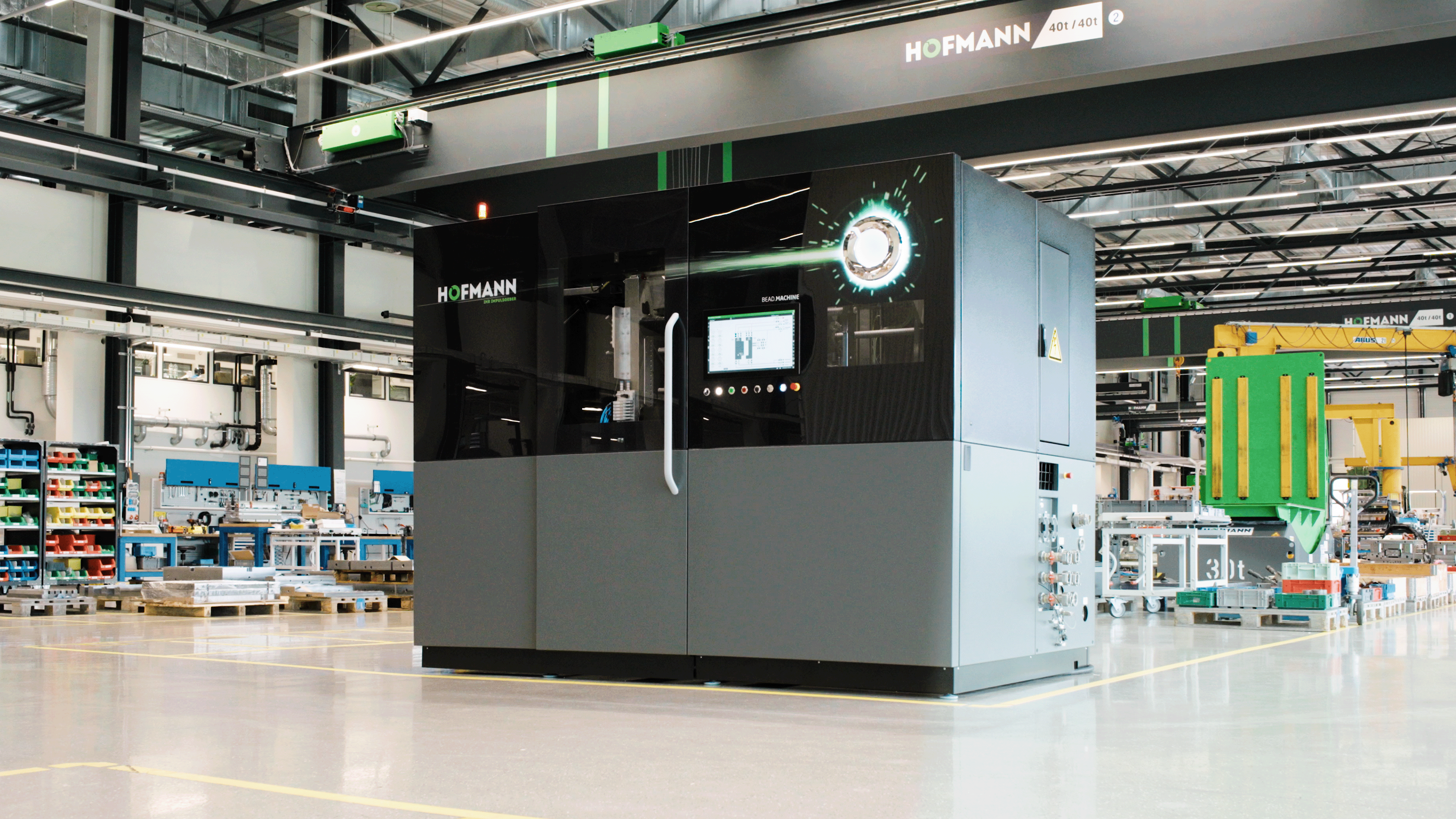

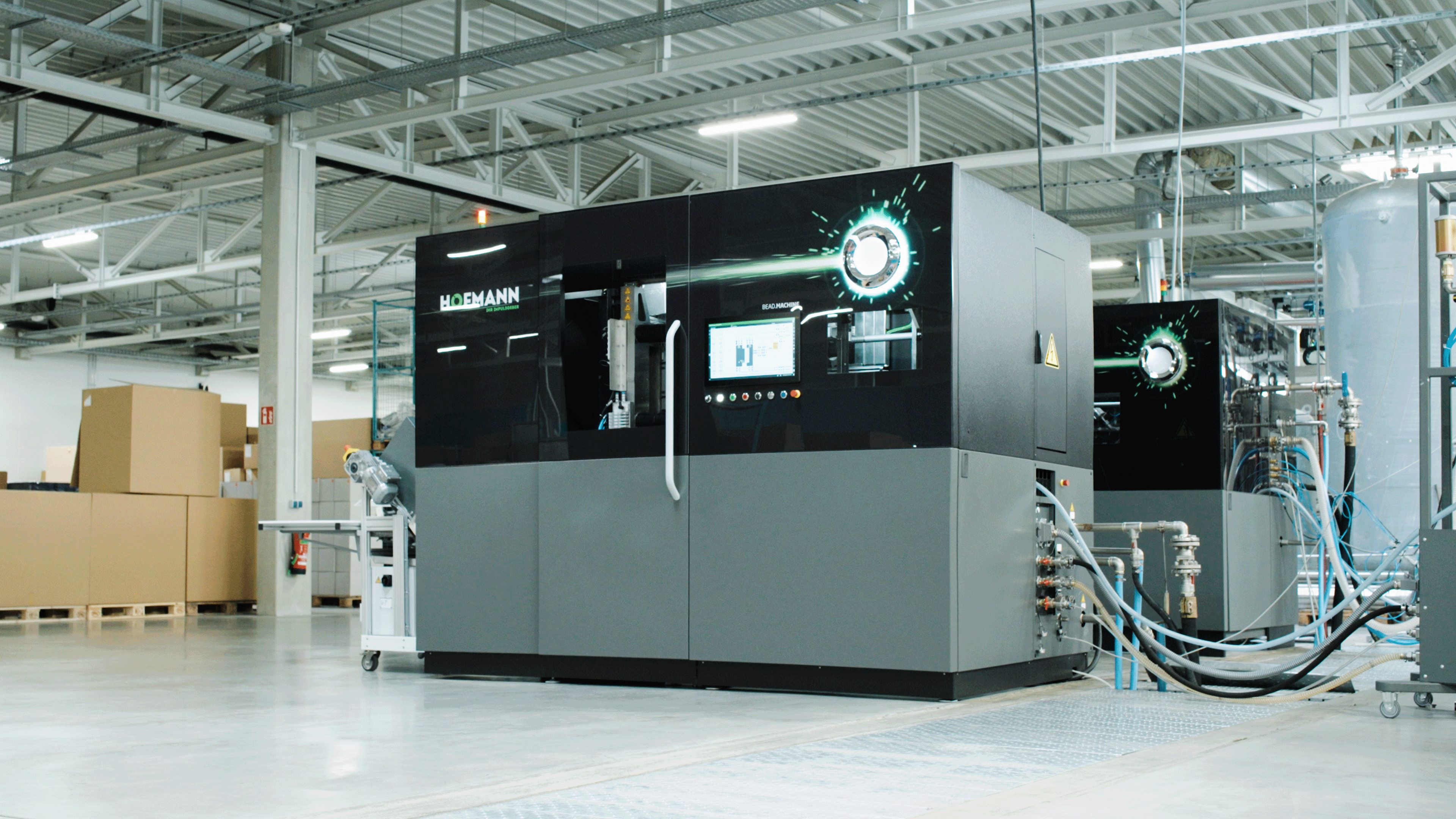

Thanks to its small footprint of 5.8sqm2, the BEAD.MACHINE particle foam moulding machine fits into even the smallest production halls – and onto a regular truck. This simplifies logistics and reduces transport costs.

Thanks to the Plug and Produce system your BEAD.MACHINE is ready to use quickly. Only a minimum of peripheral equipment is required to complete the system.

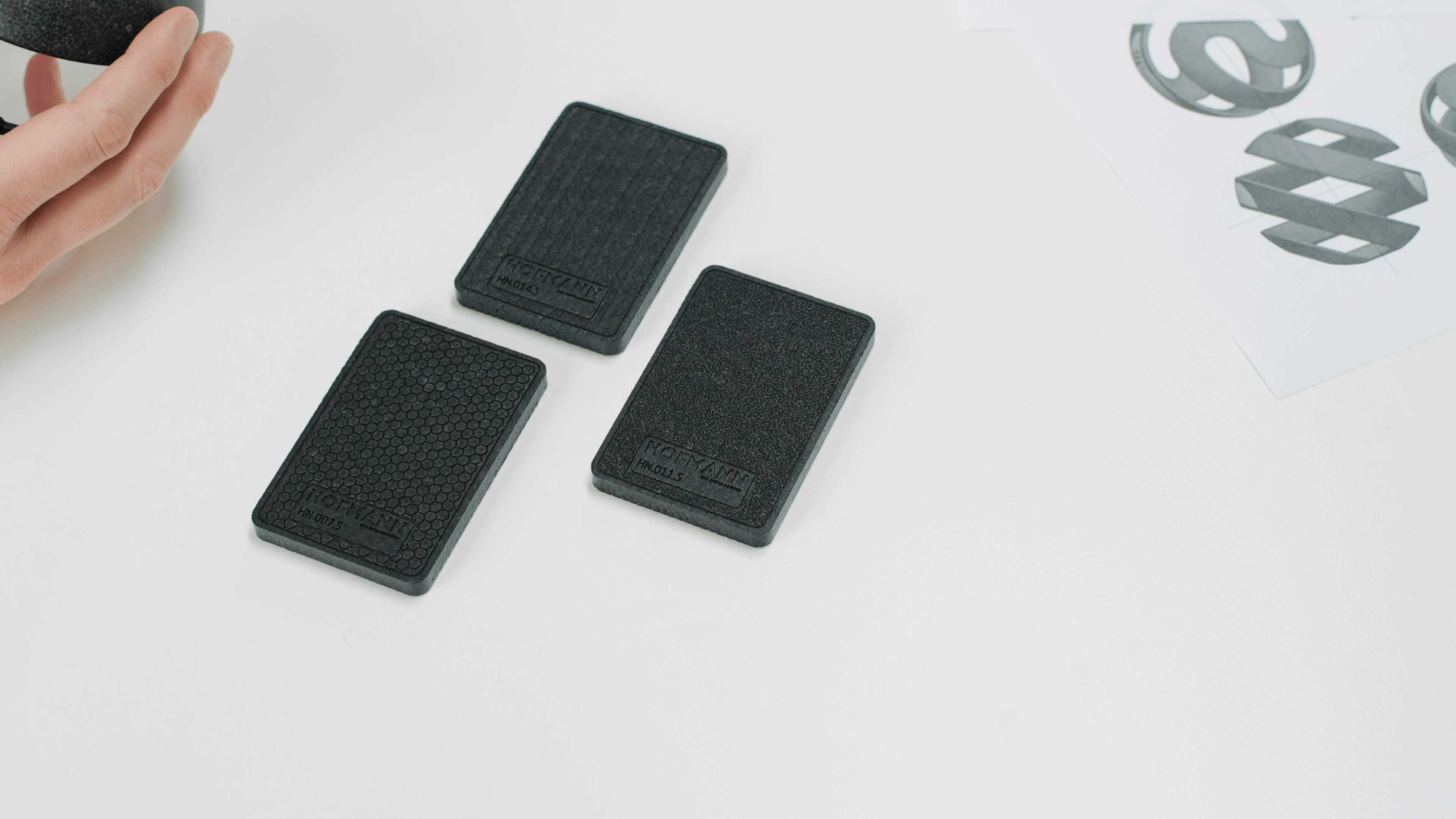

New design possibilities due to smooth surfaces without nozzle outlets allow creative product shapes.

Fine details and patterns are also easily possible due to the patented surface technology. This shape molding machine has the capability to transform unimaginable concepts into particle foam!

Particle foam shape moulding machine

Filling bin

optional

optional

> Parallelism of clamping plates: ± 0,01 mm

> Plate positioning accuracy: ± 0,01 mm

> Max. traverse speed: 450 mm/sec

EPP, EPA, ETPU, EPS, EPE, m-PPE

> Foam plastic inlays within the mould

> Material tests on request

Dirk Bernhardt

Project Director - Particle foam / BEAD.MACHINE

T: +49 9571 766-9660

vertrieb@hofmann-impulsgeber.de