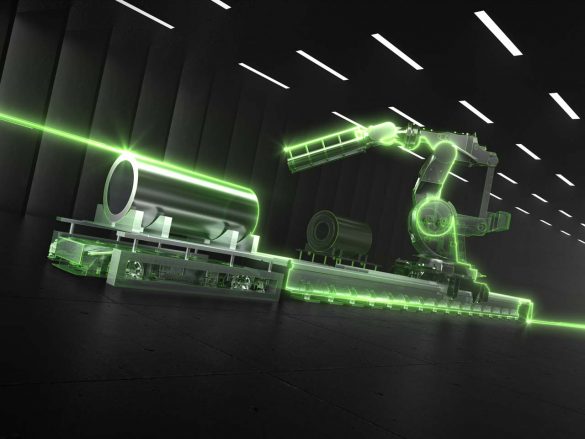

Innovative and high-quality with the help of technology and expertise

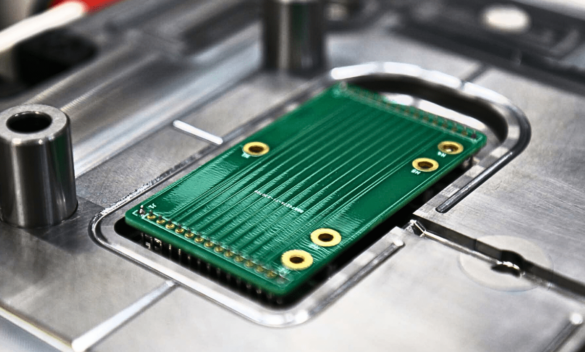

We and our customers have particularly high standards for injection moulding tools for medical technology. We make perfect use of synergies with automation and mechanical engineering. Trust our innovative ideas to make the right impact.