Drag the image to the left to see more.

Service and support for our customers

Get to know all of our services.

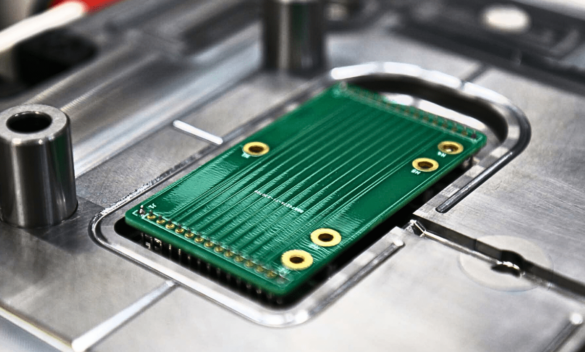

Tools for 2K fins for adjustable motor cooling

Navigation system panel, radio panel, IMD and film insert moulding (design panels)

High-pressure injection valves (hybrid components) Air duct parts

Navigation system panel, radio panel, IMD and film insert moulding (design panels)

Tools for exterior mirrors with GID/2K technology

Tool for power window systems (door beams/rail gliders)

Tool for A, B or C-column panels with 2C or 3C technology

Tool for spoilers with assembly injection moulding technology

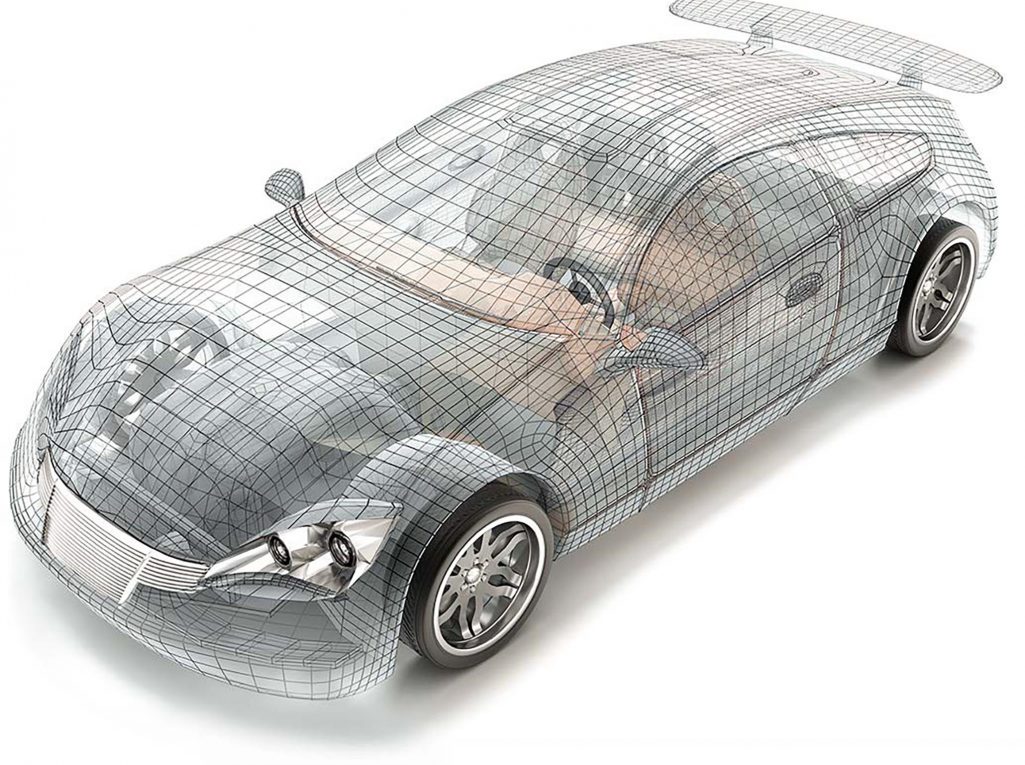

Impactful ideas for every demand

Hofmann Impulsgeber is there for you with a high degree of expertise in many technologies and industries. In the automotive industry, we have solutions for a large number of customer requirements. Trust in the experience of real experts. Our ideas meet your demands.

Your partner for the automotive industry

Stefan Hofmann

Managing Director

T: +49 9571 766-9660

vertrieb@hofmann-impulsgeber.de