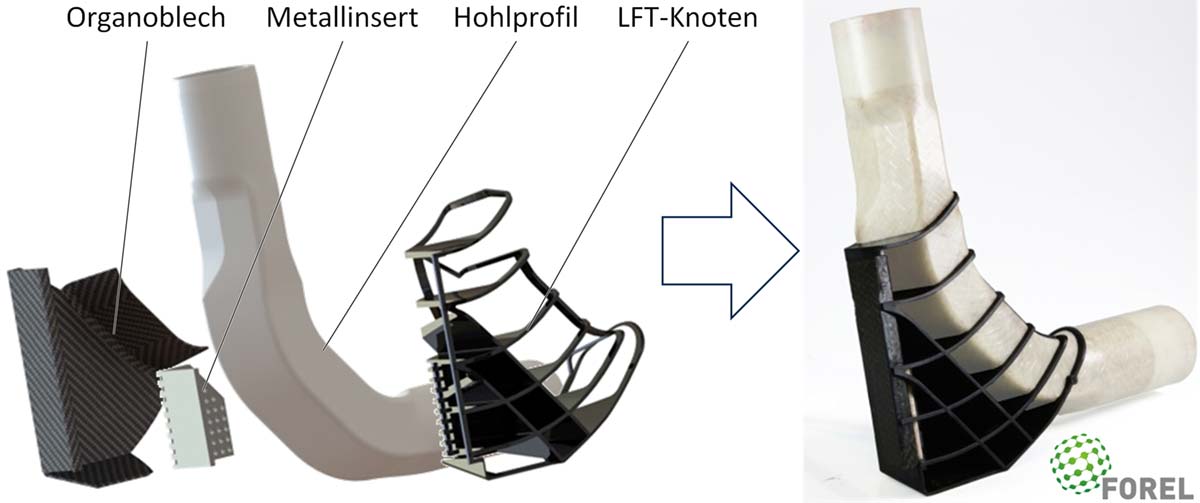

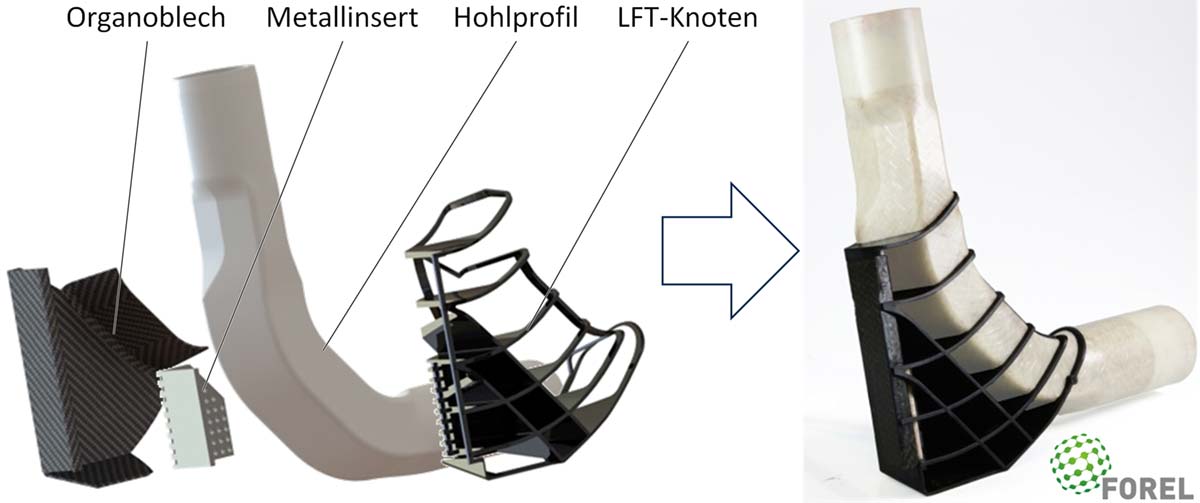

Those involved in the FuPro research project have developed a self-contained process chain, from the fibre, manufacture of semi-finished products, preforming and consolidation of the hollow profile to injection moulding. The experts attached great importance to a holistic approach in which each step of the process was rethought and optimised for the requirements of lightweight construction. Important optimisations were also made with regard to suitability for large-scale production.