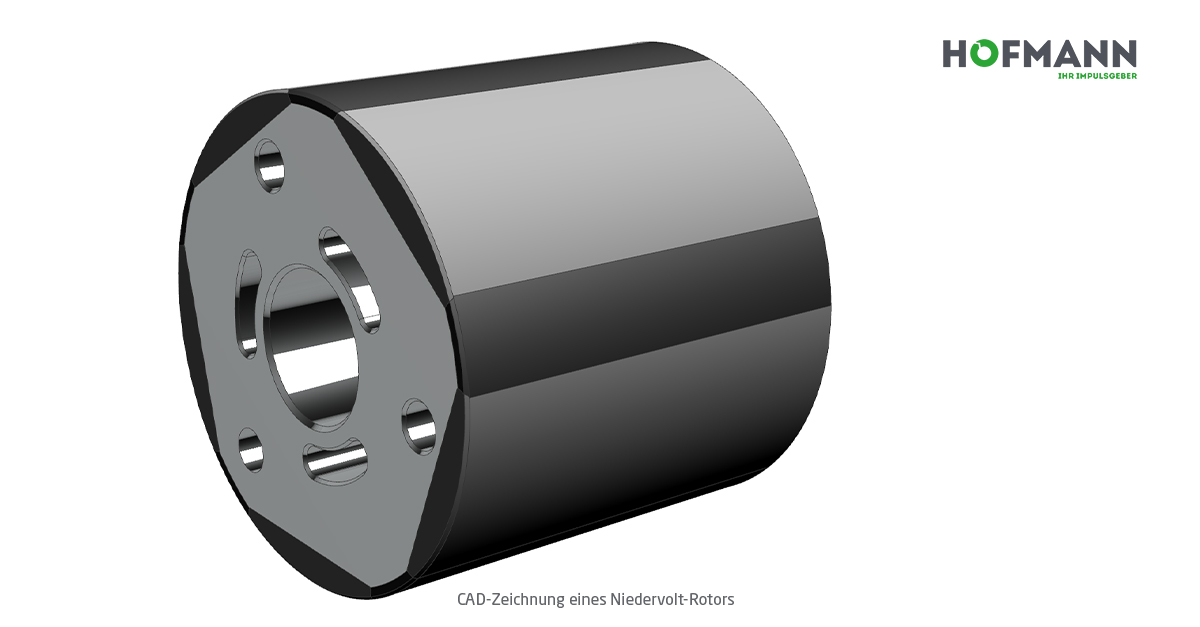

Impulse for e-mobility: production cell for rotor assembly

Electrification is becoming increasingly important in automotive engineering as part of the mobility revolution. This trend is evident in traction drives in the high-voltage range as well as in auxiliary drives on a low-voltage basis (12V/48V). At the heart of every electric motor are the rotors.

For the production of low-voltage rotors, we realize turnkey production cells including injection moulding tools for high production volumes. Several robot systems ensure complete process automation with one hundred percent traceability of the components.

The following is a selection of our expertise, which we apply for the benefit of our customers, depending on the specific requirements of the application:

- Automated material handling via AGV systems

- Separation of rotor components

- 100% in-line quality control of individual components

- Magnet assembly

- Temperature control

- Robots, handling & gripper systems

- Injection moulding tool

- Injection moulding process / process engineering

- Quality testing: geometric quantities, force testing, etc.

- Component coding

- Component cleaning

- 100% traceability

- Scalability of the system